Search

10,000 km Push

Road equipment sales were 7,002 units in FY2025, and with MoRTH’s 10,000 km highway target for next year, demand prospects appear uncertain.

Govt Defers OTR-2024 Implementation to September 2026

The OTR-2024 was to come into effect from August 28, 2025

“IoT-enabled technologies are revolutionising construction equipment.

Manav Kohli, Chief Operating Officer, Gainwell and Head, Caterpillar Dealership Business, speaks on the key trends shaping the construction equipment industry in India and globally.

Maximising Uptime

India bearings market is projected to reach $6714.8 million by 2032, growing at a CAGR of 13.5 per cent from 2024 to 2032.

BharatBenz heavy-duty rigid truck launched in India

Comes with an all-new BharatBenz 6.7-litre BSVI Stage 2 diesel engine

Some of our products use recycled material

VG Sakthikumar, Managing Director, Schwing Stetter India

Our company is focused on digital transformation

Ammann ELBA batching plants are designed taking into consideration the minutest details,†says Anand Sundaresan, Managing Director, Ammann India, while speaking on the safety features incorporated in their range of concrete equipment.

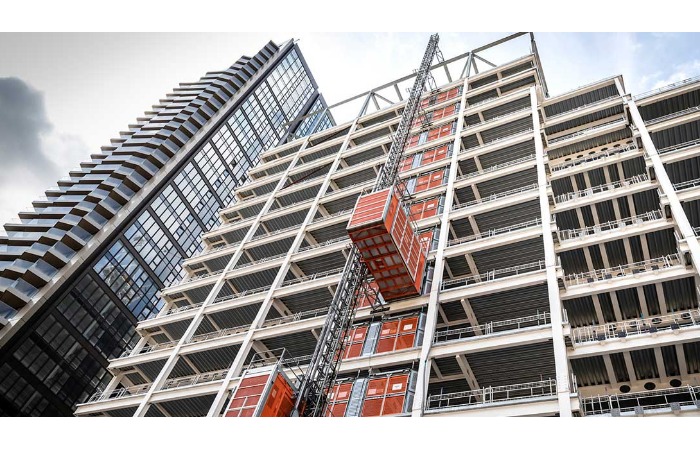

Soaring high!

Demand for construction hoists in India is expected to continue growing, as the country invests in infrastructure projects and the construction of commercial and residential buildings continues to expand.

Enhancing efficiency

India’s construction equipment market is growing quickly, and this is stimulating demand for bearings. The bearing industry is expected to grow at a rate of 9 to 10 per cent in the years ahead.

Lifting up!

The hoist market is expected to grow at a CAGR of up to 7.3 per cent till 2025.

On the Move!

The market for mobile cranes is on the move driven by low-rise residential, commercial, and industrial building construction activity in urban areas.

Major challenge is lack of standardisation of safety norms

Indiabulls Store One is leading rental equipment provide working on PAN India basis.

Demand for pick n carry cranes has strong correlation with industrial growth

The India mobile crane market is anticipated to register annual growth rate of over 5 per cent during the forecast period 2020-2025. Unfortunately, Due to unexpected Covid-19 pandemic, we can expect some challenges in terms of upcoming projects in India.

Portable compressors play major role in mining, infra and construction applications

The construction sector has been again impacted by the onset of the second wave of the Covid-19 pandemic.

B&R India completes expansion of new warehouse & repair facility

B&R India, one of the leading automation company in India recently extended its warehousing & logistics space at Chakan, Pune as a response to continuous growth the company is experiencing and foreseeing in the future.

L&T bags NHRbeML appoints new Director (rail & Metro business)CL contract Safety norms for CEVs Safety norms for CEVs

Amit Banerjee has been appointed as Director (Rail & Metro Business) and Member on the Board of BEML.

MoRTH notifies new safety norms for construction equipments vehicles

The Ministry of Road Transport and Highways (MoRTH) has issued a notification GSR 673 (E) dated 27 October 2020 in respect of Construction Equipments Vehicles (CEVs) to holistically address the issue of safety requirements.

MoRTH proposes safety norms for construction equipment vehicles

The Ministry of Road Transport and Highways has issued a draft notification to address the issue of safety requirements while construction equipment vehicles are running on roads along with other vehicles

Can Mobile Cranes Lift the Mood?

Mobile cranes in India have transformed into safer and productive with changing design and new features to meet the upcoming demands from the user market. In the current scenario, can these developments in mobile cranes lift the market sentiments?

VECV resumes manufacturing in seven plants

VE Commercial Vehicles (VECV) announced the resumption of manufacturing operations in seven of its plants in the country. These plants located in Pithampur, Dewas, and Baggad in Madhya Pradesh and Thane in Maharashtra have resumed lean operations after the required permissions were granted by the state government.

VECV resumes manufacturing operations in seven plants

VE Commercial Vehicles (VECV) announced the resumption of manufacturing operations in seven of its plants in the country.

VECV resumes manufacturing operations in seven plants

VE Commercial Vehicles (VECV) announced the resumption of manufacturing operations in seven of its plants in the country.

Schaeffler India restarts Savli plant

Schaeffler India announced the resumption of operations in Savli plant in Vadodara. The operation in the plant situated in GIDC Park resumed post government approval and following all safety norms directed by the Ministry of Home Affairs (MHA).

Setting New Benchmark

Growth in warehousing and logistics sector is picking up with the introduction of GST and infrastructure status to logistics. In this scenario, the warehousing and material handling equipment players are gearing up to meet the emerging demand for advanced equipment.

Epiroc launches blasthole drill, mine truck

The two machines were launched at IMME 2018 Kolkata by SK hattacharya, Director (Mining) Hindustan Copper.

We create the right product mix for customer productivity

Portable air compressors play a pivotal role in quarrying and mining applications. The quarrying application specifically, is a segment of paramount importance, looking at the amount of stone which is required for infrastructure projects.

New Growth Avenues

Warehousing segment in India is evolving fast and is moving towards palletised loads which can be stored at heights.

AWPs: Safe working at heights

There is always risk involved in working at heights. Introduction of aerial work platforms has made it easy for workers perform well without any risk of falling, leading to timely completion of the work with higher productivity.

Making rapid strides

Motor graders have seen unprecedented growth in the past couple of years, which is expected to continue in the coming years as well with road projects continue to grow.

We expect good growth in demand for compressors

The equipment industry is in constant evolution where there is not just product innovation but also application innovation. New technology also creates new opportunities and improved ways of using equipment.

Indian customers are gradually becoming safety conscious

Aerial Work Platforms (AWPs) can make a difference in a company?s day to day operation. There is a broad spectrum of models with a variety of lift heights suitable for almost any work requirement.

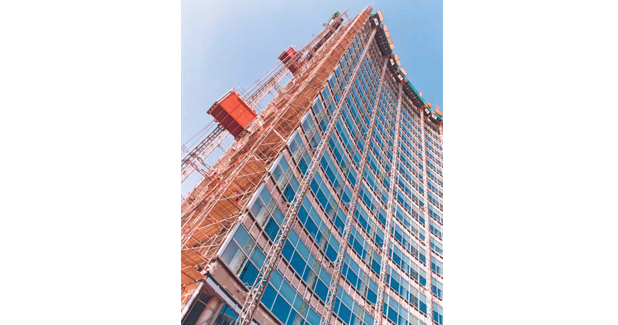

On A High!

High-rise construction is catching up momentum with more and more sky scrapers of 300 m and above are coming up in India. With these high-rise constructions, Indian construction industry is gradually moving towards the next level of technology which has necessitated the use of new and improved construction equipment to meet the demand of safe and quality construction.

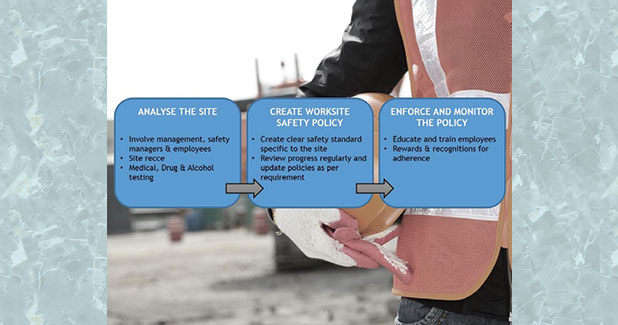

?Zero-Incident? Construction Sites

The Indian Construction Equipment (CE) industry is going through a growth phase. It is evolving faster compared to a decade ago. With the new government approach being high on governance, their initiatives have opened doors to new and multiple infrastructure projects.

Leadership Through Innovation

Volvo Trucks entered the Indian commercial vehicle (CV) industry 17 years ago with a clear goal, to drive the change. The company focused on the mining transportation segment in India and realised that our brand promise was more relevant than ever before.

Safety and Productivity at Heights

With the projects are going taller, demand for safe and productive vertical reach equipment is on the rise. Working at height has always been associated with a risk factor.

High Expectations

With growing safety awareness, the Aerial Work Platforms (AWPs), one of the best solutions to keep people safe, while working at heights, is poised for exponential growth in the near future.

Safety at Heights

For personnel working at heights safety is the diktat! Aerial Work Platform (AWP) assists the technicians to safely work at heights using their work tools. Continuing our series this edition elaborates on the safety features

Make in India

Prime Minister Narendra Modi has launched an ambitious campaign ?Make in India?, which aims to turn the country into a global manufacturing hub. The campaign projects India as an investment destination and develop, promote and market India as a leading manufacturing destination and as a hub for design and information.

Lifting Solutions

The future trend in material handling systems will be towards lighter, higher-efficiency equipment. The power consumption, material of construction, operating noise levels and eco-friendly features of this equipment will play a big role while introducing

Maximising Output

Several key trends are emerging in the asphalt/soil compaction market where performance and productivity remain key issues. The OEMs are keen to maximise output from their latest units in terms of improving machine performance, O&M cost and operator safety and comfort.

Crawling Now, To Pick Up Soon?

Despite the muted demand due to lack of new projects in the power sector, the crawler cranes segment is expected to register good growth once the new projects are taken up after the general elections, writes Sudheer Vathiyath.India is a huge market for crawler cranes, especially higher capacity crawlers. This is mainly due to increasing demand in thermal power sector, nuclear power sector, steel plants, refinery expansions and wind power sector. However, the market has slowed down in the last tw

Intelligent Lifting Solutions

Steel industry has the toughest and most demanding operating conditions. Equipment India finds out intelligent lifting solutions offered by major players. Lifting equipment in the steel industry is subject to the roughest conditions like extremely high and variable ambient temperatures, difficult and heavy loads

Our cranes have some of the best safety features.

Demag is probably the only company among crane manufacturers with the largest field force. Our services include installation and commissioning, warranty and post warranty services and support through parts, says Vidyakant Miraje, Business Head - Process Cranes, Demag Cranes and Components (I). Excerpts from the interview.

We plan to launch multi-functional man and material handling hoists at Excon 2013.

Spartan has always been a trendsetter in bringing hoists with world class designs and internati?onal safety features. Our multi-functionality approach to hoists has put us in the big league of innovative, value added products, says Vikram Mehta, Managing Director, Spartan Engine?ering. Excerpts from the interview.

We enjoy a monopoly in some segments because of the matchless attributes we offer.

Moba has rich expertise in mobile automation backed up by robust electronics, sensors with high quality, and strong technical application knowledge which has enabled Moba to build solutions which are effective, reliable and easy to operate. Such systems demand the withstanding the highest degree of vibration, exposure to dust, water and heat

We understand how important it is to pay attention to our customer needs.

The future of material handling equipment is going to be about more automation and easier human control interface, says Tushar Mehendale, Managing Director, ElectroMech. Excerpts from the interview.

We are leaders when it comes to providing simple and effective solutions for intra-logistics.

We have solutions to lift and carry loads right from 500 kg to 250 tonne. We have provided solutions for material handling needs over 190 years and our name is synonymous with quality and reliability in material handling across the world

+91-22-24193000

+91-22-24193000 Subscriber@ASAPPinfoGlobal.com

Subscriber@ASAPPinfoGlobal.com